Comprehensive Guide to Electric Motor Rebuild and Repair Services

Table Of Contents

Key Takeaways

- Comprehending electric machines is crucial for effective maintenance and refurbishment.

- The refurbishment procedure for electric machines involves systematic evaluation and repair.

- Essential actions in motor restoration are vital for achieving optimal performance.

- Techniques for reassembly are important for ensuring reliability in electric machine refurbishment.

- Testing and ensuring quality in motor restoration are key to successful operation.

- Advantages of expert electric machine refurbishment include enhanced efficiency and longevity.

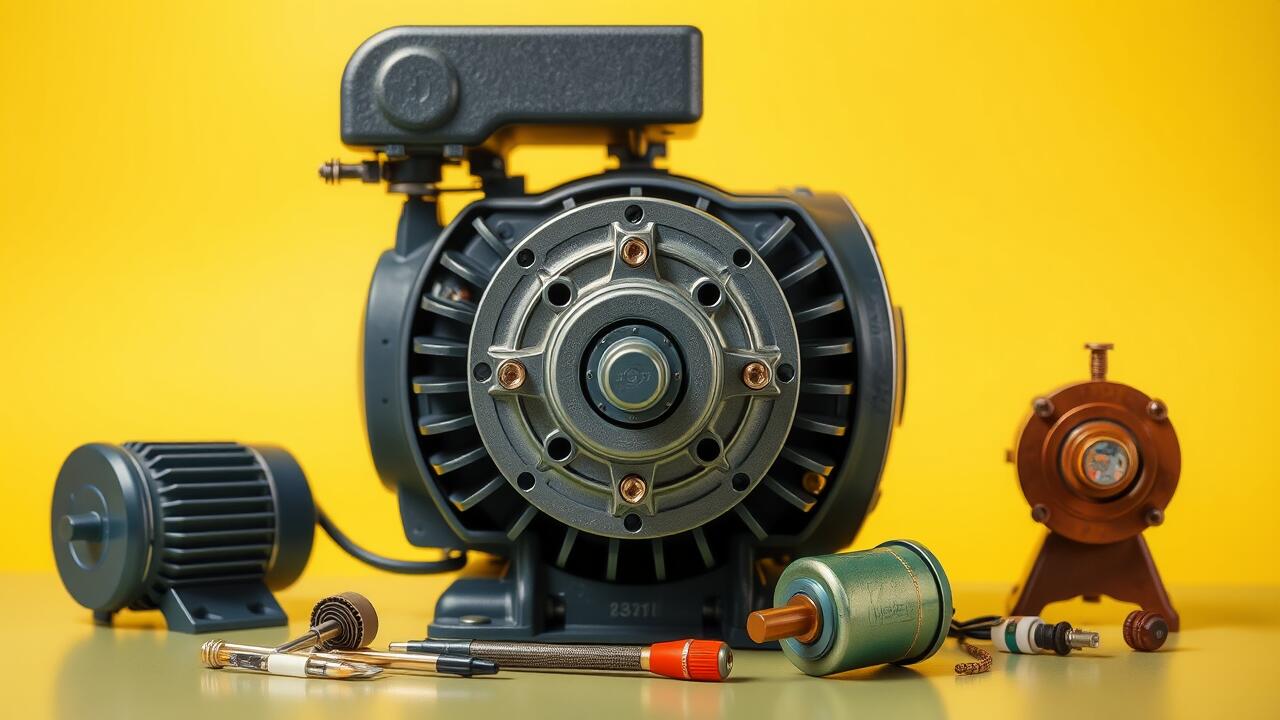

Understanding Electric Motors

Electric motors are crucial components in various industries, driving everything from household appliances to industrial machinery. In an electrical system, the efficiency of an electric motor directly impacts performance, making proper maintenance essential. An electric motor rebuild focuses on restoring the functionality of the motor while ensuring that all components, including the motor controller, operate optimally. Understanding the types of electric motors and their operational principles offers insights into voltage requirements and performance characteristics. Effective rebuilding not only enhances the lifespan of the motor but also contributes to overall cost efficiency compared to complete replacement.

Types of Electric Motors

Electric motors come in various types, each suitable for specific applications. AC motors and DC motors are the two primary categories. AC motors typically operate using alternating current and are popular for their energy efficiency, especially in industrial settings. Within these categories, different designs, such as induction and synchronous motors, feature distinct rotor designs and coils. The quality of electrical insulation and the use of advanced materials can significantly enhance performance, making these motors more reliable during an electric motor rebuild.

Another significant type includes stepper and servo motors, which are commonly used in precision applications. These motors provide excellent control over motion, allowing for accurate positioning and speed regulation. In rebuilding these motors, technicians often reverse-engineer the components to restore functionality. Effective use of roller bearings and careful inspection of rotors are essential in ensuring optimal performance. A well-executed electric motor rebuild can greatly contribute to the longevity and efficiency of electric motors across various industries.

- Electric motors are crucial in both industrial and residential applications.

- AC motors are widely used for high-efficiency tasks, such as in large machines and HVAC systems.

- DC motors excel in applications requiring variable speed control, like electric vehicles and robotics.

- Stepper motors are perfect for applications demanding precise control, such as in 3D printers and CNC machines.

- Servo motors offer precise motion control and feedback for robotics, conveyor systems, and automation.

- The choice of materials in motor construction impacts durability and performance significantly.

- Regular maintenance and timely rebuilding can lead to significant cost savings and extended motor life.

Common Applications of Electric Motors

Electric motors are widely used across various sectors, powering machines that range from household appliances to industrial equipment. Common applications include HVAC systems, where motors drive fans and compressors, and conveyor belts in manufacturing, where they provide movement and efficiency. An electric motor rebuild can help to restore the functionality of these motors by addressing issues such as worn coil wires and damaged bearings, including sleeve, thrust, ball, and roller bearings. By employing reverse engineering techniques, technicians can accurately determine the specifications needed for parts replacement and refurbishment.

In the automotive industry, electric motors are integral to electric and hybrid vehicles, enabling smooth operation of systems like windows, seats, and steering. The precision of these motors is crucial, as improper alignment or malfunctioning components can lead to decreased performance. An electric motor rebuild ensures that the motor operates effectively by focusing on the quality of the coil, wires, and bearings involved. With an emphasis on maintaining the integrity of the motor components, this process enhances the overall reliability and longevity of machines in various applications.

The Electric Motor Rebuild Process

An electric motor rebuild involves a systematic approach to restore functionality and efficiency. This process begins with an initial assessment, focusing on critical components such as the bearings and insulation system, which are essential for optimal operation. Attention is given to the winding resistance to ensure the motor can handle the desired horsepower safely. During disassembly, technicians carefully inspect rolling element bearings and other parts for wear and damage. The potential energy stored in the motor must be managed effectively, especially in applications like compressors, to prevent operational failures. Rebuilding not only addresses immediate concerns but also enhances the overall longevity of the electric motor.

Initial Assessment and Diagnosis

A thorough initial assessment plays a critical role in any electric motor rebuild. Technicians begin by examining the motor's insulation and overall condition, looking for signs of wear or damage. They often check for abnormal vibrations that may indicate issues with the windings or misalignment within the motor. Manufacturers typically provide guidelines regarding acceptable efficiency levels, which can help technicians identify performance gaps. By integrating various sensors, specialists can gather data that informs the diagnosis, ensuring a comprehensive understanding of the motor's health.

Following the visual inspection, technicians will delve deeper into the components of the motor. This involves testing the integrity of the wire and other essential parts, which is fundamental in determining whether a rebuild is viable or if replacement is necessary. Any deterioration in the windings can severely impact performance, thereby affecting the overall efficiency of the motor. Understanding these factors allows for a more targeted approach during the electric motor rebuild process, ultimately leading to a more effective repair strategy.

- Conduct a visual inspection to identify any visible wear or damage.

- Monitor vibrations to detect winding issues or misalignment.

- Compare motor performance against manufacturer efficiency guidelines.

- Utilize various sensors to collect detailed data on motor health.

- Assess the condition of wiring and other critical components.

- Determine the viability of rebuilding versus replacing the motor.

- Develop a tailored repair strategy based on the assessment findings.

Disassembly of the Electric Motor

The disassembly phase of an electric motor rebuild is crucial for a successful motor repair. This step involves carefully removing various components to access the interior parts of the motor. Technicians must pay close attention to the arrangement and condition of components to identify signs of electric motor failure, which can affect motor efficiency. Proper documentation during this process can streamline the typical motor repair that follows and ensure that all parts are accounted for.

A systematic approach to disassembly is essential in the motor repair industry. It requires precision to avoid damaging any parts that may still be functional. Technicians should utilize specialized tools designed for motor repair to facilitate the process. As each component is removed, it becomes easier to inspect them for wear and tear, setting the stage for effective refurbishment during the electric motor rebuild. This meticulous attention to detail ultimately contributes to the overall success of the motor repair process.

Key Steps in Motor Repair

Inspection of components plays a crucial role during the electric motor rebuild process. It involves a thorough evaluation of each part against the original motor design, ensuring that all components meet prevailing motor repair standards. This careful assessment is essential for the motor repair market where quality motor repair services are in high demand. Motor manufacturers often rely on experienced technicians at a reputable motor repair shop to identify wear and tear in parts. Following inspection, cleaning and refurbishing parts become necessary, particularly for applications like compressor motor rebuilt services. The combination of these steps ensures durability and reliability, setting a benchmark for excellence in motor repair.

Inspection of Components

A thorough inspection of components is crucial during the electric motor rebuild process. Each part must be examined for wear and damage, as these factors can affect the performance of a reassembled motor. Motor techs often check bearings, windings, and rotor alignment to ensure they meet the requirements of an independent motor. This step is vital for motor repair customers who rely on the functionality and reliability of their motors.

Identifying defective components can significantly influence the success of a motor repair service. By addressing issues early, motor repair technicians can preserve the integrity of the functional motor, ultimately leading to a longer lifespan. Inspecting components carefully sets the foundation for a successful electric motor rebuild, ensuring that the final product meets the high standards expected by motor repair customers.

Cleaning and Refurbishing Parts

Cleaning and refurbishing parts play a crucial role in the electric motor rebuild process. Thoroughly cleaning components such as motor windings and casing helps to remove contaminants that can lead to motor failures. Many motor repair shops utilize specialized techniques and products to ensure that all pieces are free from dirt and debris. This attention to cleanliness significantly enhances motor performance by providing a more reliable foundation for reassembly. Investing time in this phase can prevent future issues related to motor protection and longevity.

Refurbishing worn parts is equally important for optimal functioning. This step often involves assessing the condition of components and determining which can be repaired versus those that need replacement. Standardized motor designs allow for interchangeable parts, which simplifies this process. Effective motor repair remedies can include resurfacing bearing surfaces or replacing insulation to ensure that motor windings remain intact. By focusing on these aspects, the overall durability and efficiency of the electric motor rebuild are greatly improved.

Reassembly Techniques for Electric Motor Rebuild

Achieving a successful electric motor rebuild requires precise reassembly techniques to ensure optimal performance. In a motor shop, careful attention is paid to aligning motor cores properly to prevent issues such as bent motor shafts. Each component must be reattached based on the specifications for the specific horsepower motors being repaired. Mechanical modifications may sometimes be necessary to enhance durability and performance. The motor failure decision often hinges on the quality of reassembly, which significantly impacts the longevity and efficiency of the rebuilt motor, making it critical to adhere to industry standards throughout the process.

Ensuring Proper Alignment

Achieving proper alignment during an electric motor rebuild is crucial for optimal functionality. Misalignment can lead to increased wear on mechanical parts and exacerbate electrical system problems. A quality motor service ensures that every component is positioned correctly, reducing the risk of failure. Skilled technicians utilize precision tools to align the motor shaft with the drive system, facilitating efficient operation and minimizing energy loss. This attention to detail safeguards against issues that may arise from old wiring repair and enhances the performance of the rebuilt motor.

The role of an experienced electrical team cannot be underestimated in this process. They understand the significance of aligning components to allow for full voltage operation without undue strain on the motor. Accurate alignment not only extends the lifespan of the rebuilt electric motor but also promotes safety and reliability in performance. By following established protocols and utilizing best practices, the alignment phase becomes a pivotal step in the overall success of the electric motor rebuild, ensuring the system operates as intended.

| Component | Tools Used | Alignment Process | Benefits |

|---|---|---|---|

| Motor Shaft | Laser Alignment Tool | Check alignment using laser beams | Reduces wear and tear |

| Drive System | Dial Indicator | Adjust until within tolerance standards | Facilitates efficient operation |

| Bearings | Alignment Bars | Level and align the bearings properly | Extends lifespan of components |

| Electrical Connections | Torque Wrench | Tighten according to specifications | Enhances safety and reliability |

Torque Specifications for Motor Components

Proper torque specifications are essential in the electric motor rebuild process. They ensure that all components are securely fastened, preventing issues during operation. In a current repair shop, adhering to these specifications is critical for the longevity of driven equipment. Incorrect torque can lead to failures under transient voltage conditions, compromising the performance of the motor. Ensuring the right alignment and torque on components like coil bracings significantly contributes to the reliability demanded by the European motor market.

Employing suitable electrical insulation methods during the rebuild also plays a pivotal role in maintaining the integrity of the motor. Mechanical handling of the components should be conducted with care to avoid damage, as improper torque can cause misalignment or, worse, lead to catastrophic failures. A well-executed electric motor rebuild not only enhances performance but also prepares the motor to withstand challenging operational environments.

Testing and Quality Assurance in Motor Repair

Quality assurance procedures are critical in the electric motor rebuild process, ensuring that every component meets industry standards. Running performance tests evaluates the mechanical force exerted by the rebuilt motor while verifying that correct replacement bearings and custom bearings are correctly installed. Electrical testing procedures focus on the wiring, checking for proper connections and re-insulation where necessary. Through these rigorous assessments, the repair industry upholds the reliability and safety of rebuilt motors, ultimately enhancing their performance and longevity. Each step in the repair process is essential for achieving optimal results and ensuring that the motor will function efficiently in its intended application.

Running Performance Tests

Performance testing is a critical phase following an electric motor rebuild, ensuring that all repairs have been executed correctly. During this process, technicians monitor variables such as current winding removal and the integrity of the new windings installed. Observations regarding coil movement help identify any potential rotor rub issues that might arise. Proper alignment and balanced installation are vital to achieving optimal performance from the rebuilt motor.

Running performance tests also involve examining cap wiring to confirm that all connections are secure and functioning as intended. Any discrepancies in the electrical parameters may indicate underlying issues that could compromise the effectiveness of the electric motor rebuild. By systematically assessing each component, professionals can ensure that the motor operates smoothly and efficiently, prolonging its operational lifespan.

Electrical Testing Procedures

A thorough electrical testing procedure is essential for any electric motor rebuild to ensure the functionality and safety of the repaired motor. Skilled repair techs start by examining the winding configuration and testing the integrity of the lead wires. This diagnostic phase helps identify any electrical anomalies that may have arisen during use or as a result of the previous failure. Having an adequate equipment inventory allows techs to perform these tests accurately and efficiently, ultimately leading to a good repair.

Qualified repair shops prioritize electrical testing to confirm that all components are performing within specified parameters. They meticulously check the element bearings and other critical parts to guarantee that the motor operates smoothly under load. Any discrepancies found during the testing phase may necessitate further repairs or adjustments to enhance performance. This comprehensive approach ensures that the electric motor rebuild meets industry standards and provides reliable operation for its intended application.

Benefits of Professional Electric Motor Rebuild

Opting for an electric motor rebuild offers substantial advantages over outright replacement, particularly concerning cost efficiency. A skilled technician can assess and enhance the insulation integrity of components like core bolt insulation and shafts, ensuring they meet performance standards. Local repair shops often provide detailed repairs, including winding doesn and addressing any wear that may compromise functionality. Investing in an electric motor rebuild not only extends the life of the equipment but also enhances its reliability, making it a prudent choice for those seeking sustainable solutions.

| Benefit | Description | Impact |

|---|---|---|

| Cost Efficiency | Rebuilding typically costs less than purchasing a new motor. | Significant savings on operational costs. |

| Improved Reliability | Rebuilt motors are often tested and certified for optimal performance. | Increased confidence in motor functionality. |

| Customized Repairs | Skilled technicians tailor repairs to specific motor needs. | Greater longevity of equipment through targeted fixes. |

| Environmental Sustainability | Rebuilding and repairing reduces waste and conserves resources. | Positive contribution to eco-friendly practices. |

Cost Efficiency Compared to Replacement

Many repair shops specialise in electric motor rebuilds, providing a cost-effective alternative to complete motor replacement. This process often focuses on assessing and repairing specific damaged parts such as the winding and shaft. Quality repair services can restore the electric motor to its original operating efficiency, significantly reducing expenses compared to purchasing a new unit.

Investing in an electric motor rebuild not only saves money but also extends the lifespan of the motor. By refurbishing existing parts rather than replacing them entirely, businesses can maintain their operational capacity while avoiding the high costs associated with new equipment. The overall financial benefits become clear when factoring in both the price of parts and the expertise required for proper repairs.

Extension of Motor Life

An electric motor rebuild can significantly enhance the lifespan of a motor by ensuring that its key components, such as coils, bearings, and wires, are in optimal condition. Reverse engineering techniques allow technicians to identify wear patterns and potential failure points. By replacing or refurbishing critical parts like sleeve bearings, thrust bearings, and ball and roller bearings, the efficiency of the machine is restored, reducing the risk of unexpected breakdowns.

Through a meticulous electric motor rebuild process, the overall performance of the motor is improved, which translates to a longer operational life. Precision in replacing components and the careful calibration of the rebuilt machine contribute to enhanced durability. With regular maintenance and timely rebuilds, the electric motor can continue to perform effectively while avoiding the costs associated with complete replacement.

Conclusion

An electric motor rebuild can significantly extend the lifespan of motors, making it a cost-effective alternative to replacement. Many motor shops specialise in diagnosing and repairing issues such as bent motor shafts or damaged motor cores. Identifying the right mechanical modifications can enhance performance, particularly for high-horsepower motors. The motor failure decision often hinges on the extent of damage and the potential for a successful rebuild. By prioritising quality and precision during the rebuild process, technicians ensure reliability and optimal performance for various applications.

FAQS

What steps are involved in the electric motor repair process to ensure a successful outcome?

The motor repair process for an electrical motor typically involves several crucial steps. Initially, the motor is disassembled, where components like the rigid coil are inspected for damage. After this, the parts may be cleaned or replaced as needed, and any issues are reverse-engineered to identify the root cause of failure. Finally, reassembly occurs, followed by testing to confirm that the motor is fully operational.

What are the essential tools required for an effective electric motor rebuild?

For an effective electric motor rebuild, you will need essential tools such as a multimeter for testing electrical components, a torque wrench for proper assembly, and various hand tools like screwdrivers and pliers to disassemble and reassemble parts. Having a good workbench and workspace is also vital for a successful electric motor rebuild.

What common issues can arise during an electric motor rebuild?

During an electric motor rebuild, common issues can include problems with electrical connections, worn bearings, and damage to the stator or rotor. Ensuring proper assembly and alignment is crucial to avoid these setbacks, which can hinder the motor's performance and longevity. Regular maintenance and inspections can help mitigate these issues during an electric motor rebuild.

How can I determine if an electric motor rebuild is necessary for improved performance?

To determine if an electric motor rebuild is necessary, check for signs of wear and overheating, listen for unusual noises during operation, and monitor performance issues such as reduced torque or inconsistent speeds. Regular maintenance can prevent the need for an electric motor rebuild and help sustain optimal functionality.

What benefits can I expect from a professional electric motor rebuild compared to doing it myself?

A professional electric motor rebuild can offer numerous advantages, including expert diagnostics, precision workmanship, and access to specialized tools, resulting in improved performance and longevity of your motor.