Diagnosing Over-Lubrication in Enclosed Electric Motor Housings

Key Takeaways

- Measuring the appropriate quantity of grease is crucial for optimal function.

- Excessive lubrication can lead to performance issues and inefficiencies.

- Identifying and fixing problems caused by too much lubricant is essential for motor health.

- Understanding the importance of lubrication intervals can save you from future headaches.

How Can You Measure the Right Amount of Lubricant?

To measure the right amount of electric motor grease, a calibrated pump can be your best friend. Using a grease gun designed for precision, you gain the ability to dispense a consistent amount each time. Typically, industry standards suggest adding lubricant based on the motor's size and operational speed. For example, a small motor may require only one or two pumps, while larger motors can demand up to ten. Keep a checklist handy to ensure you’re aligned with the manufacturer's specifications to avoid the unfortunate fate of over-lubrication.

Another valuable snack-sized tip is using a grease fitting equipped with a sight glass. These magical little devices give you a clear view of the lubricant level, allowing you to make adjustments without resorting to guesswork. For motor lubrication, maintaining the proper volume not only enhances efficiency but prolongs the life of your equipment. Regular check-ins every three months can save you from an unwelcome motor meltdown. Following recommendations from the Electric Machinery Association, this practice ensures you strike that perfect balance between too little and too much.

Tools and Techniques for Finding Your Motor's Goldilocks Zone

When aiming for that unbeatable balance of electric motor grease, consider a straightforward approach with a variety of measuring tools that resemble your grandma’s kitchen scale. A simple hand pump with a pressure gauge provides immediate feedback as you gauge how much the grease seeps into the bearings. Over-lubrication can be identified not just by feel, but also by sound; if your motor sounds like it’s thrumming to a classic rock tune, it’s time to reassess your lubrication game.

Don’t underestimate the power of the periodic maintenance schedule either. An inspection every three months ensures that you’re not playing grease roulette. Data from industry studies show that motors well-maintained through scheduled lubrication last over 20% longer than their neglected counterparts. Implementing a system where you log lubricant amounts might sound as exciting as watching paint dry, but it pays off. After all, keeping your electric motor in its Goldilocks zone of lubrication can prevent plots of grease from leading to catastrophic motor meltdowns.

The Effects of Over-Lubrication on Performance

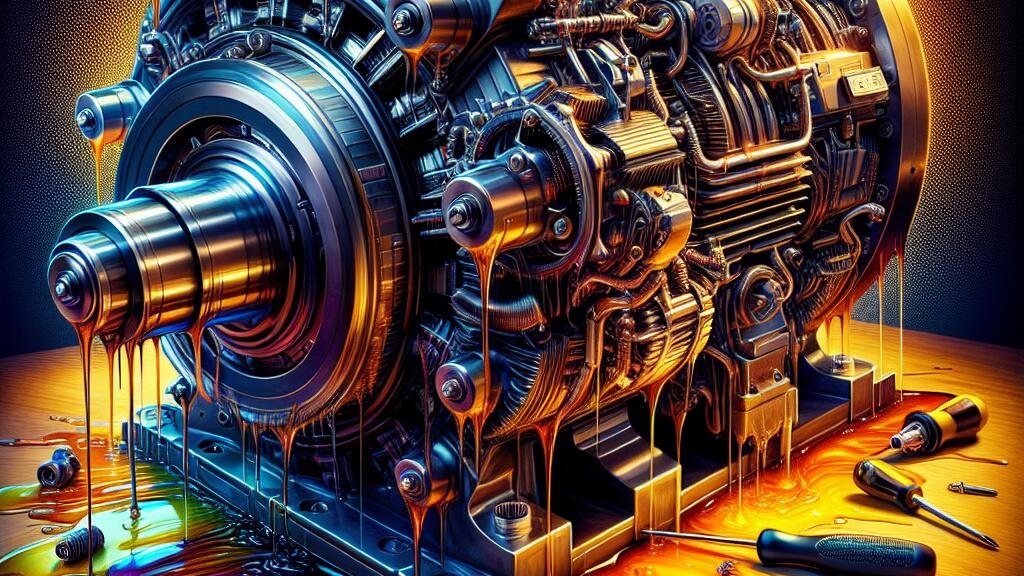

When it comes to electric motor lubrication, too much of a good thing can lead to a slippery slope of disaster. Applying excessive electric motor grease transforms your motor from a well-oiled machine to a greasy villain that struggles to perform. The lubricant can enter unexpected nooks and crannies, obstructing important electrical components like windings and bearings. This gooey excess may not just be annoying; it’s the equivalent of pouring too much sauce on a pizza—delicious at first glance, but a mess when you try to take a bite.

Motors drowning in over-lubrication tend to overheat faster than a summer barbecue. Increased friction from the grease clogs can lead to a significant rise in operating temperatures, sometimes exceeding 200°F. A study by the Electrical Apparatus Service Association indicates that up to 25% of motor failures can trace their origins back to lubrication issues. So, if your motor starts sounding like a restless sleeper, it could be crying out for attention. Monitoring lubrication levels is not just a chore; it’s essential to keeping your motor humming along instead of sputtering in oily despair.

When Too Much of a Good Thing Leads to Motor Meltdown

Too much electric motor grease is like inviting the entire neighborhood to a dinner party—all it takes is one cranky neighbor to spoil the festivities. Over-lubrication can create a sticky situation where the excessive grease clumps together, impeding the smooth operation of your motor. Imagine attempting to sprint through molasses; that’s akin to what your bearings experience. In fact, studies indicate that nearly 35% of motor failures stem from improper lubrication, often involving an overly generous application of lubricant.

Picture this: a bustling factory floor where machinery works like a well-oiled machine—literally. Now, imagine chaos erupting as a motor seizes because it’s drowning in too much electric motor lubrication. As gears and components get bogged down in a gooey mess, the risk of overheating skyrockets. The science backs this up, revealing that even a small excess of grease can lead to a staggering 20% decrease in efficiency, ultimately causing premature motor failure. Regularly checking lubrication levels and using the right amount can save time, money, and sanity—because nobody enjoys scrubbing out a greasy disaster.

Troubleshooting Your Over-Lubricated Motor

When troubleshooting an over-lubricated electric motor, it often feels like trying to bring an elephant back to a mouse’s party. First, disconnect the motor and open the housing. Brace yourself for a lubricant explosion, as you might find more electric motor grease than a mechanic’s workshop during a full moon. Use absorbent materials to soak up excess grease. You’ll want to treat it like a spillage of guacamole at a fiesta; swift and clean to avoid a slippery situation.

Next comes the delicate task of assessing lubrication levels. If your grease fitting resembles a fountain rather than a fine-tuned lubrication system, a deeper inspection is in order. Consider employing a suction device to remove excess grease. Be wary of damage; using sharp tools may leave unwanted nicks. Implement a scheduled maintenance plan adhering to manufacturer specifications and industry standards. This ensures that your motor’s lubrication frequency stays in line with what’s necessary, promoting longevity instead of a lube-induced meltdown.

Step-by-Step Guide to Reviving a Greasy Disaster

First, assess the situation. If your motor resembles a buttered popcorn machine rather than a finely tuned piece of machinery, act quickly. Disconnect the power before beginning your operation; no one wants an accidental jolt while you’re elbow-deep in electric motor grease. With a clean bucket ready, carefully unscrew the housing, allowing any excess lubrication to drain. You might encounter a slippery mess—think less Picasso and more abstract disaster—but don't fret; heroic feats of motor maintenance happen in the trenches.

Next, grab your trusty lubricant extraction tool or a simple shop vacuum. It’s time to channel your inner mechanic superhero. Proceed to remove all excess electric motor lubrication with precision, ensuring you don’t leave any residue behind like a bad roommate who forgot to clean up after themselves. After a thorough cleaning, reference manufacturer guidelines for the ideal amount of lubrication. Add the correct quantity of lubricant, transforming your once-overwhelmed motor from a greasy disaster into a well-oiled machine, ready to get back to work.

Why Should You Care About Lubrication Frequency?

Imagine your electric motor as a well-maintained sports car—too much oil, and you might as well be trying to run the Indy 500 through a kiddie pool. Finding the right lubrication frequency is crucial; manufacturers recommend routine maintenance intervals based on operating conditions. For instance, greasing a motor every 500 operating hours is a typical guideline. However, if you let those hours roll by like stale bread, you risk both excessive heat and, ironically, a sticky situation caused by electric motor grease that turns into goo, ruining the party for everyone inside the housing.

Consider that sweet spot where your motor hums along like a perfectly tuned orchestra while enjoying its electric motor lubrication. If you’re prone to slacking on grease schedules, you’ll end up with bearings whining louder than a toddler at nap time. Data shows that over-lubrication can reduce bearing life by as much as 52%. Keeping a keen eye on lubrication timing will ensure not just performance longevity, but also avoidance of motor meltdowns—an occupational hazard that nobody wants to explain at the next staff meeting.

The Impact of Timing on Motor Longevity

Timing your electric motor lubrication is crucial. Overzealous greasing can turn a well-oiled machine into a greasy disaster. Imagine an electric motor housing so clogged that it considers itself a new form of modern art. The ideal frequency isn’t always obvious. For example, motors used in heavy-duty applications might need fresh electric motor grease every three months, while lighter duty counterparts might stretch that to six months. Recognizing the right intervals ensures the grease doesn’t become a gooey trap but instead serves its purpose effectively.

Take the time to create a lubrication schedule based on the manufacturer's recommendations and operational conditions. Some motors even come equipped with sensors that can signal when they’re in desperate need of attention. By monitoring these indicators, you can avoid disastrous over-lubrication that leads to overheating and premature failure. Regular attention will not only improve performance but extend the lifespan of your electric motor. Remember, a well-timed lube job is much better than a last-minute grease attack, which could have your motor crying for help.

FAQS

What’s the secret to finding the right amount of lubricant for my motor?

Think of it as a Goldilocks scenario—too little, and your motor gets cranky; too much, and it’s like a motor party gone wild! Use measuring tools and techniques to find that sweet spot where your motor feels just right.

How do I know if my motor is suffering from over-lubrication?

If your motor is leaking like a bad faucet or sounding like a cat in a blender, it’s time to check for over-lubrication. Also, if it’s producing more grease than a pizza parlor, you're in trouble!

Can over-lubrication really lead to a motor meltdown?

Absolutely! Too much grease can cause overheating and create a slippery situation that no motor wants to be in. It’s like trying to run a marathon in a sauna—nobody's going to finish well!

What’s the first step in troubleshooting an over-lubricated motor?

Step one—don’t panic! Then, grab a towel and start wiping away the excess grease. After that, follow our step-by-step guide to revive your motor from its greasy disaster. It’s like giving your motor a spa day!

Why should I care about how often I lubricate my motor?

Think of lubrication frequency like feeding your pet—you wouldn’t want to overdo it and end up with a sickly pup! Regular intervals keep your motor happy and running longer, avoiding those awkward greasy moments.