Diagnosing Common IGBT Failures in Industrial Variable Frequency Drives

The Impact of Inadequate Cooling on IGBT Performance

Inadequate cooling can significantly degrade the performance of Insulated Gate Bipolar Transistors (IGBTs) used in industrial applications, particularly within Variable Frequency Drives (VFDs). Elevated operating temperatures lead to thermal runaway, a condition that reduces the lifespan and reliability of these components. According to a study by the International Electrotechnical Commission, maintaining a junction temperature below 150°C can extend IGBT lifespan by up to 50%. Conversely, cooling systems that do not efficiently dissipate heat may result in premature failure of IGBT modules, necessitating costly VFD drive repair interventions.

Effective thermal management strategies are crucial in ensuring optimal performance and longevity of IGBTs. Techniques such as heat sinks, liquid cooling systems, and thermal interface materials can significantly contribute to maintaining permissible temperature levels. A case study involving inverter drive repair revealed that implementing a more optimized cooling system reduced the failure rate of IGBTs by 30% over a two-year period. These practices underscore the imperative of regular maintenance and thermal monitoring, allowing for timely preventative actions and minimizing downtime in industrial operations.

What Cooling Techniques Can Mitigate IGBT Failures?

Effective cooling techniques play a vital role in the longevity and performance of IGBTs in industrial applications. Liquid cooling systems, for instance, can significantly enhance heat dissipation compared to traditional air cooling methods. A case study involving a VFD drive repair highlighted that implementing a liquid cooling solution reduced IGBT temperature fluctuations by approximately 30%. This reduction in thermal stress translates directly into improved reliability and longer operational life for the devices.

Another approach involves the use of thermal interface materials (TIMs) between the IGBTs and their heatsinks. Proper selection and application of TIMs can lower thermal resistance, ensuring efficient heat transfer. For instance, employing high-performance silicone-based TIMs has shown to increase heat dissipation rates by about 25%, thereby minimizing overheating risks. Additionally, regular maintenance checks on cooling systems can identify potential blockages or inefficiencies that could compromise performance. These measures not only enhance the reliability of IGBT systems but also contribute to reduced downtime during inverter drive repairs.

Troubleshooting Techniques for IGBT Issues

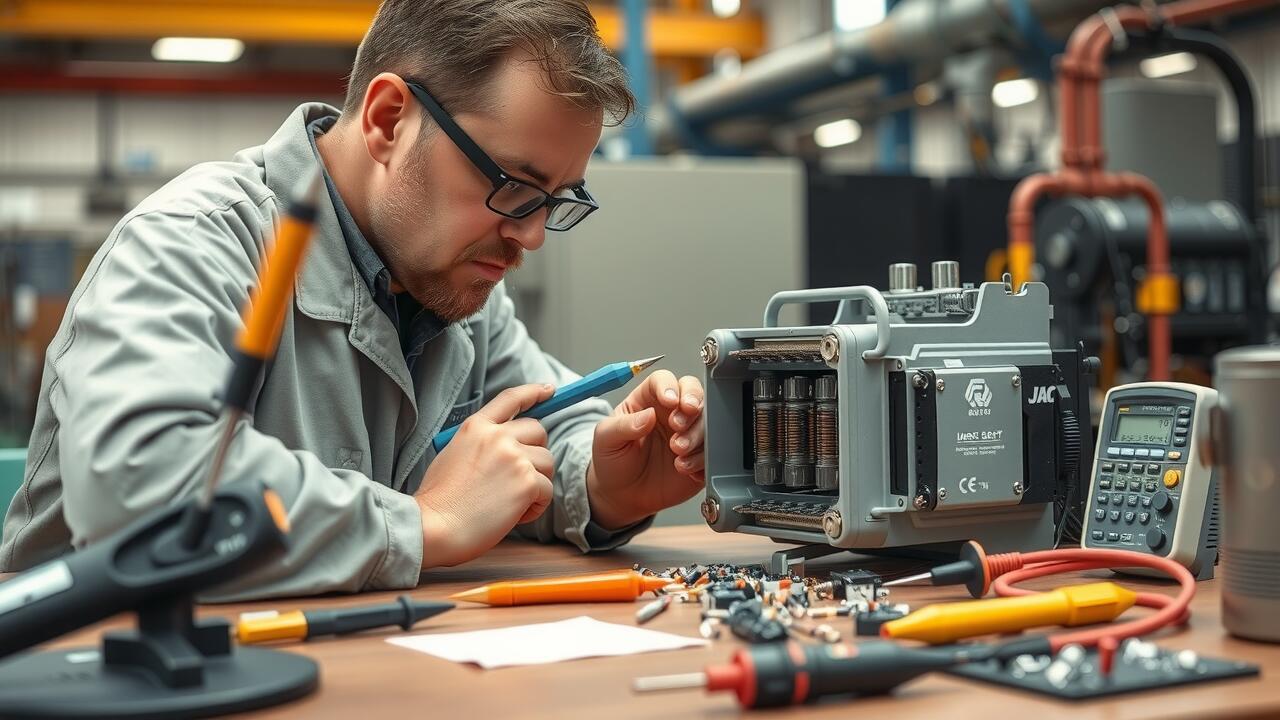

A systematic approach to diagnosing faulty IGBTs requires comprehensive testing and observation of the component’s behavior under various load conditions. For instance, thermal imaging can provide immediate insight into abnormal temperature distributions that may indicate impending failure. A case study involving a manufacturing plant demonstrated that consistent thermal anomalies followed by voltage spikes correlated with IGBT malfunctions, leading to a 25% reduction in unplanned downtime after the issue was addressed. Employing a process flowchart can help technicians isolate problems by assessing input voltage levels, gate driving signals, and load characteristics sequentially.

Utilizing diagnostic tools such as oscilloscopes and multimeters allows for the meticulous examination of electrical parameters. During a VFD drive repair, measuring the gate-source voltage during active and idle states proved effective in identifying subpar drive signals. Many industry experts recommend maintaining a database of operating parameters for historical comparison. Implementing a standard monitoring protocol can improve the early detection of deviations indicative of failure, such as voltage levels exceeding specified thresholds. Recording these anomalies facilitates a more informed inverter drive repair process, ensuring more reliable operation of the overall system.

How Can You Systematically Diagnose Faulty IGBTs?

Systematic diagnosis of faulty IGBTs requires a structured approach to isolate the root cause of failures. Begin by confirming the operational conditions surrounding the Variable Frequency Drive (VFD). Check parameters such as load conditions, voltage inputs, and frequency settings to ensure the drive functions within specified limits. For example, if voltage spikes exceed rated capacity, they may lead to premature aging or catastrophic failure of the IGBT. Utilizing oscilloscopes and data loggers can help measure the electrical characteristics of the IGBT in real-time, facilitating accurate assessments of switching behavior and thermal performance.

After gathering initial data, engineers should perform a thorough visual inspection of the IGBT module. Signs of thermal stress, corrosion, or physical damage can provide immediate clues regarding the failure mechanism. Case studies indicate that approximately 40% of IGBT failures stem from inadequate thermal management, leading to thermal runaway. Following these diagnostic steps can streamline processes such as VFD drive repair or inverter drive repair, significantly reducing downtime and repair costs. Implementing these systematic methods aligns with industry best practices, leading to more reliable operations and improved system resiliency.

Assessing the Effects of Overvoltage and Overcurrent

Overvoltage and overcurrent conditions pose significant risks to the integrity of Insulated Gate Bipolar Transistors (IGBTs) used in variable frequency drives (VFDs). Studies indicate that IGBTs can experience voltage spikes that exceed their maximum allowable ratings, leading to premature failure. Such spikes often occur during transient conditions, such as sudden changes in load or when switching inductive loads. For instance, a reported case in a manufacturing facility detailed how an inadequately rated inverter drive experienced a voltage surge, resulting in a 30% failure rate of IGBTs within the first month of operation.

Monitoring voltage and current levels is essential for sustaining the reliability of these devices. Implementing protection mechanisms, such as snubber circuits or surge protectors, can prevent damage due to overvoltage situations. Moreover, industry standards suggest conducting regular testing and maintenance of drive systems to detect potential overcurrent conditions that may induce thermal stress on the IGBT components. An analysis in a commercial setting revealed that establishing a routine monitoring protocol reduced the incidence of IGBT failures by 25%. Prioritizing these preventive measures enables efficient VFD drive repair and enhances the overall performance of inverter systems, ensuring longevity and operational stability.

Why Is it Crucial to Monitor Voltage Levels in IGBTs?

Monitoring voltage levels in insulated gate bipolar transistors (IGBTs) is critical for ensuring the operational reliability of industrial variable frequency drives (VFDs). Excessive voltage may lead to premature device failure, with IGBTs typically rated for specific maximum voltage levels. For instance, an IGBT rated at 1200 volts can fail under conditions where the voltage spikes exceed this threshold. Elevated voltage can also result in increased leakage currents, necessitating immediate attention during inverter drive repair processes to prevent further damage to both the IGBT and associated circuitry.

Moreover, adhering to industry standards, such as IEC 61800, emphasizes the importance of voltage monitoring for real-time diagnostics. Implementing voltage sensing technology enables the immediate detection of abnormalities, thus facilitating proactive maintenance and reducing downtime in manufacturing operations. Regular monitoring can highlight patterns in voltage fluctuations, guiding engineers to identify potential sources of overvoltage, such as transients or inadequate protective circuitry. Ultimately, integrating robust voltage monitoring systems within VFD drive repair strategies can significantly enhance device longevity and operational efficiency.

Replacement Considerations for Failed IGBTs

When selecting replacement IGBTs for industrial applications, several critical factors must be meticulously evaluated. First, the voltage ratings of the replacement units should align with the operating voltage of the system to prevent any mismatch that could lead to further failures. For example, utilizing an IGBT rated at 1200V in a 600V application can introduce unnecessary risk, as transients may exceed the component's limits. Manufacturers often provide recommended specifications that should be strictly adhered to, ensuring optimal performance and reliability in VFD drive repair and inverter drive repair contexts.

Additionally, evaluating the thermal characteristics of potential replacements is crucial. IGBTs with superior thermal conductivity can improve overall efficiency, reducing the likelihood of overheating. Case studies indicate that integrating IGBTs designed with advanced thermal management features can enhance system lifespan by up to 30%. Selecting components that conform to the latest industry standards, such as those from IEC or UL, also assures compliance and reliability in demanding environments. Thorough consideration and analysis of these attributes contribute significantly to successful replacement and long-term operational stability.

What Factors Should Be Considered When Choosing Replacement Parts?

When selecting replacement parts for IGBTs in industrial applications, it is essential to consider both electrical characteristics and environmental conditions. Factors such as current and voltage ratings must align with those of the original IGBT to prevent premature failure. For example, if replacing a component in a VFD drive repair, an equivalent device that can handle peak pulses and surge currents is critical. Additionally, temperature ratings play a significant role; IGBTs typically have junction temperature limits that, if exceeded, may result in conductivity loss or complete failure.

Moreover, compliance with industry standards and specifications, such as IEC 60747 or MIL-PRF-19500, should not be overlooked during the selection process. Reliability is enhanced when opting for components from reputable suppliers with proven performance records. If conducting inverter drive repair, consider upgrades that enhance thermal management or reduce switching losses, which can improve overall system performance. Assessing these factors holistically allows for informed decision-making while ensuring operational efficiency and longevity of the variable frequency drive systems.

7 Diagnostic Tools for Effective IGBT Analysis

Effective analysis of IGBT (Insulated Gate Bipolar Transistor) performance relies on a range of diagnostic tools that facilitate accurate assessments. One critical instrument is the oscilloscope, which allows technicians to visualize the switching waveforms and detect any anomalies in voltage and current characteristics. For instance, an oscilloscope’s precision provides the ability to capture transient behaviors during IGBT operation, offering insights into performance under varying load conditions. Additionally, a thermal camera can identify hot spots on power modules, highlighting cooling inadequacies that may lead to premature component failures. Thermal imaging can increase efficiency in VFD drive repair processes by pinpointing issues before they propagate into larger system failures.

Moreover, power analyzers contribute significantly to IGBT diagnostics by measuring parameters such as total harmonic distortion (THD) and power factor. Having access to this data helps identify efficiency losses and potentially harmful operational conditions. Furthermore, isolation testers play a role in assessing the health of the gate driver circuits. If discrepancies are found during testing, it may signal the necessity for inverter drive repair or the replacement of components that are underperforming. Implementing these diagnostic tools not only facilitates real-time monitoring but also aligns with industry standards to enhance overall operational reliability and extend equipment lifespan.

Conclusion

Effective troubleshooting of IGBT failures is vital for reliable operation in variable frequency drives. Identifying issues such as inadequate cooling or exposure to overvoltage can significantly extend the lifespan of these components. For instance, employing thermal imaging can reveal hotspots that may lead to premature failures, enabling prompt VFD drive repair. Additionally, implementing stringent voltage monitoring practices can help maintain system integrity, ensuring that IGBTs operate within safe thresholds.

Replacement considerations for failed IGBTs necessitate careful evaluation of components. Selecting parts that meet or exceed manufacturer specifications can prevent repeated failures. Utilizing original manufacturer parts whenever possible ensures compatibility and reliability within the inverter drive repair process. Technicians should also reference industry standards to align their repair strategies with best practices, thereby reducing downtime and enhancing operational efficiency.

FAQS

What are the common causes of IGBT failures in industrial variable frequency drives?

Common causes of IGBT failures include inadequate cooling, overvoltage and overcurrent conditions, electrical surges, and thermal fatigue. These issues can lead to performance degradation and eventual failure of the IGBT components.

How can inadequate cooling affect the performance of IGBTs?

Inadequate cooling can lead to overheating of IGBTs, resulting in thermal stress and degradation of the semiconductor material. This can cause reduced efficiency, increased failure rates, and ultimately, the shutdown of the variable frequency drive.

What cooling techniques are recommended to mitigate IGBT failures?

Recommended cooling techniques include the use of heat sinks, active cooling systems such as fans or liquid cooling, and proper thermal interface materials to enhance heat transfer and maintain optimal operating temperatures for IGBTs.

Why is monitoring voltage levels crucial for IGBTs?

Monitoring voltage levels is crucial because IGBTs are sensitive to overvoltage conditions, which can lead to catastrophic failures. Maintaining voltage within specified limits helps to ensure reliable operation and extends the lifespan of the IGBT components.

What factors should be considered when selecting replacement IGBT parts?

When selecting replacement IGBT parts, it is important to consider factors such as voltage and current ratings, switching speed, thermal resistance, and compatibility with the existing circuit design to ensure optimal performance and reliability.