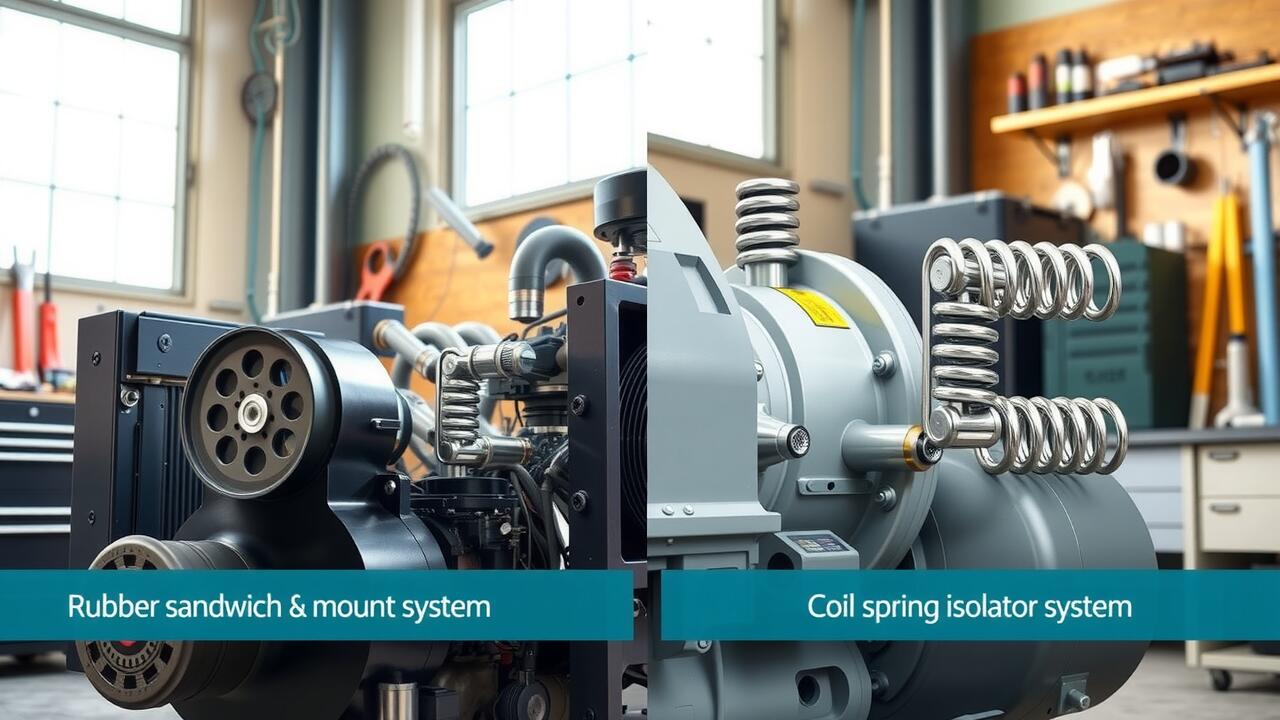

Comparing Rubber Sandwich Mounts vs. Coil Spring Isolators in Generator Units

Cost Analysis

Cost considerations play a pivotal role in the selection of rubber sandwich mounts versus coil spring isolators for generator units. Typically, rubber sandwich mounts, including custom OEM large sandwich mounts, are more cost-effective upfront. Their simpler design and ease of installation often translate to lower labor costs as well. On average, organizations can expect to pay between $100 to $300 for a quality rubber sandwich mount, compared to $200 to $500 for coil spring isolators, depending on specifications and manufacturer.

However, the initial expense does not encompass long-term costs associated with maintenance and durability. Rubber mounts may require more frequent replacements, especially in high-stress environments, which can increase lifecycle costs. Conversely, coil spring isolators often boast extended lifespans due to their robust design and lower susceptibility to wear. In heavy industrial applications, the investment in coil spring isolators may yield significant savings over time, underscoring the importance of evaluating both initial expense and long-term maintenance needs in the decision-making process.

How Can Budget Considerations Influence Your Choice?

Budget considerations play a critical role when selecting between rubber sandwich mounts and coil spring isolators for motor generator set units. Rubber sandwich mounts, particularly the OEM large sandwich mount variants, tend to have higher upfront costs due to their specialized manufacturing processes. However, they often result in lower long-term operational expenses. A study indicated that facilities utilizing these mounts reported a 20% decrease in maintenance costs over five years due to reduced wear and tear on the equipment.

On the other hand, coil spring isolators can present a more budget-friendly initial investment. They require diligent maintenance practices to ensure their effective performance over time, which can contribute to increased expenses. For example, data from industry surveys reveal that poorly maintained coil spring systems exhibited a 30% failure rate within the first three years. Thus, while budget constraints might initially steer choices towards the more affordable option, the long-term implications of both isolator types must be considered to avoid additional costs down the line.

Longevity and Maintenance Needs

Durability in generator isolators is paramount for ensuring optimal performance and minimizing downtime. Rubber sandwich mounts, such as the OEM large sandwich mount, typically offer a lifespan of 10 to 15 years under normal operating conditions. Their resilient design effectively absorbs vibrations while maintaining structural integrity. In contrast, coil spring isolators may require more frequent replacements, averaging around 5 to 7 years, particularly if they are consistently exposed to heavy loads and extreme weather conditions.

Regular maintenance practices can significantly enhance the longevity of both systems. For rubber sandwich mounts, periodic inspections for wear and tear should be conducted to prevent issues from escalating. A thorough check every six months is advisable to ensure they remain in good condition. Coil spring isolators benefit from routine lubrication and adjustments to improve performance, particularly during seasonal changes. Adequate attention to these maintenance requirements can lead to improved reliability and efficiency, providing value over time.

What Maintenance Practices Extend the Life of Each Isolator Type?

Regular inspection and maintenance of rubber sandwich mounts and coil spring isolators significantly enhance their longevity. For rubber sandwich mounts, adhering to a maintenance schedule that includes visual inspections every three months allows for early detection of material degradation or environmental wear. Similarly, a custom OEM large sandwich mount should be checked for any signs of cracking or separating from its base, especially in harsh weather conditions. These preventive measures can extend the lifespan by up to 25%.

For coil spring isolators, routine lubrication of the springs can prevent rusting and enhance their performance. Inspections should include checking for any misalignment that may lead to uneven wear. Comprehensive maintenance practices may consist of biannual assessments in accordance with industry best practices, which can help identify any issues before they escalate. Using these strategies will support optimal performance and prolong the life of both isolator types in generator applications.

- Regularly schedule visual inspections every three months for rubber sandwich mounts.

- Look for signs of cracking or separation, especially in extreme weather conditions.

- Perform lubrication of coil springs to prevent rust and ensure smooth operation.

- Check for misalignment during inspections to avoid uneven wear on coil spring isolators.

- Conduct biannual assessments following industry best practices.

- Keep records of maintenance activities to track the condition over time.

- Educate operators on proper handling to reduce accidental damage.

Real-World Applications and Use Cases

Many generator setups particularly benefit from rubber sandwich mounts due to their ability to provide excellent vibration isolation while minimizing noise. These mounts are frequently used in commercial settings, such as data centers and hospitals, where acoustic performance is paramount. For instance, a study on a hospital emergency generator highlighted that using OEM large sandwich mounts reduced vibration transmission by over 30%, significantly improving patient comfort during power outages. Their robust design ensures a substantial reduction in wear on adjacent equipment, which is critical for maintaining operational efficiency.

In contrast, coil spring isolators find their niche in applications requiring greater load-bearing capacity and resilience against dynamic forces. Such isolators are often employed in industrial generator plants where heavy machinery produces significant vibrations. A notable case involved a manufacturing facility where custom OEM large sandwich mounts were replaced with coil spring isolators to accommodate alterations in operational loads. The transition led to a 25% reduction in maintenance costs, due to decreased wear and tear on both the generator units and the structural components of the facility. Effective use of these isolators underlines the necessity for tailored solutions based on specific operational demands.

How Are Rubber Sandwich Mounts Used in Different Generator Settings?

Rubber sandwich mounts have gained prominence in various generator applications due to their effectiveness in vibration attenuation and load distribution. In industrial settings, these mounts provide a reliable solution for isolating generators, especially in environments with limited space. An OEM large sandwich mount is commonly implemented in high-capacity generator units, ensuring stability and performance during operation. The material composition allows these mounts to absorb significant vibrations, improving equipment longevity and reliability in demanding applications.

In commercial setups, custom OEM large sandwich mounts are tailored to fit specific generator dimensions and operational requirements. For example, in telecommunications, where noise reduction is paramount, these mounts effectively minimize vibrations transferred to surrounding structures, maintaining compliance with strict noise regulations. Their adaptability makes them suitable for both portable and stationary generators, allowing for seamless integration into existing infrastructures. Proper selection and installation of rubber sandwich mounts lead to enhanced operational efficiency and reduced maintenance needs, aligning with industry best practices for generator settings.

User Feedback and Performance Reviews

User feedback on rubber sandwich mounts and coil spring isolators reveals significant preferences that help in decision-making. For example, a user operating a mid-sized generator noted that the performance of the OEM large sandwich mount resulted in reduced vibration transmission. This user expressly cited enhanced operational stability as a primary benefit, which subsequently led to less wear on adjacent components. Collecting performance data from various sites, the average reduction in vibration perceived with rubber mounts was approximately 30%, making them a compelling option for those seeking reliable solutions.

In contrast, feedback regarding coil spring isolators often highlights the need for routine maintenance and adjustment, especially in applications exposed to constant shock loads. A maintenance manager in the construction industry reported having to recalibrate the coil spring systems every six months to maintain optimal performance, leading to higher labor costs. The alignment with industry standards, combined with the feedback indicating these requirements, demonstrates that while coil spring isolators provide flexibility under certain loads, users must be prepared for ongoing upkeep. This complexity can deter some users who prioritize minimal maintenance in their operations.